- Product Description, Coatings, and Functions

Product Description

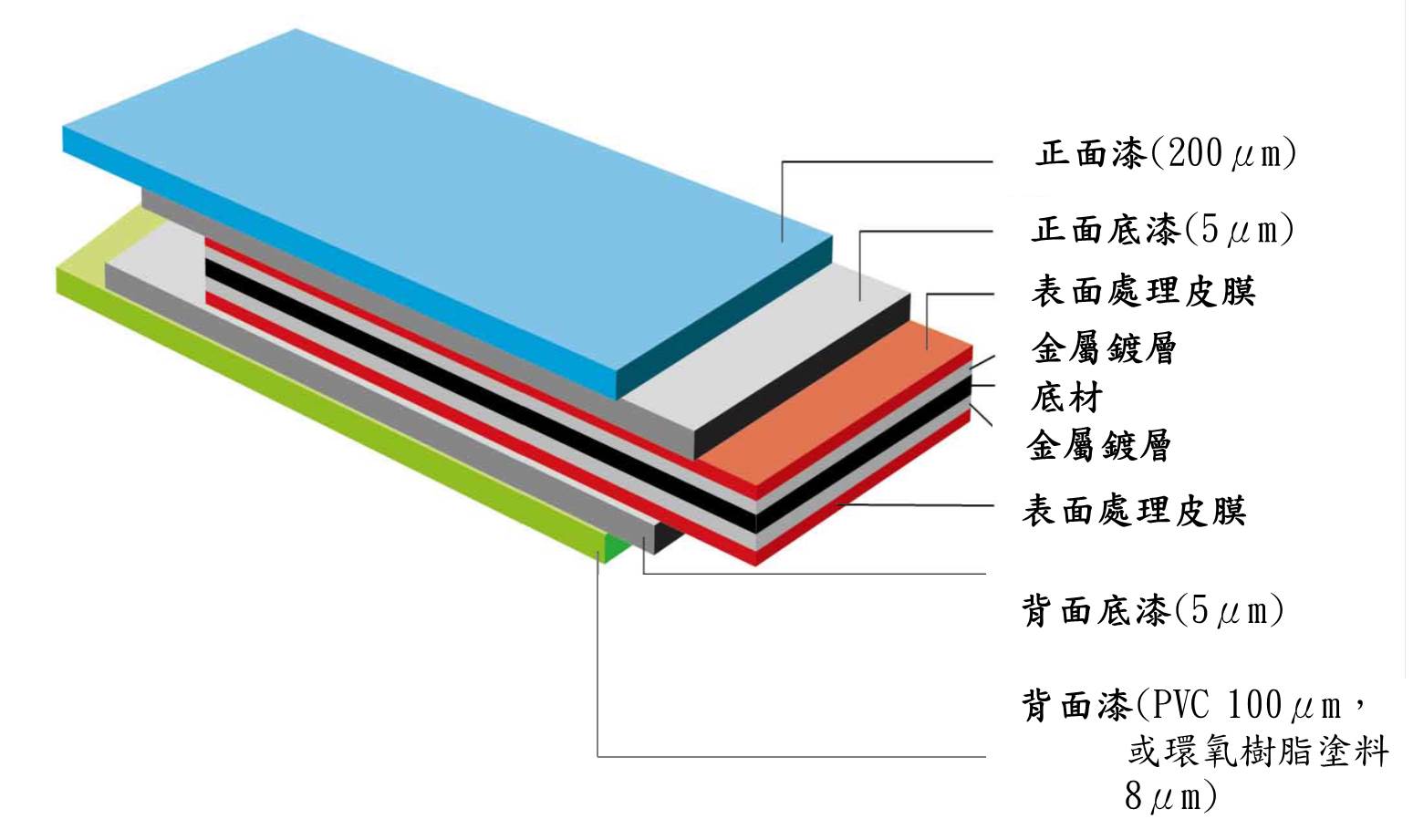

Kai Ching PVC-coated steel sheet (polyvinyl chloride resin painted steel) uses PVC molten resin coating to create a high-thickness coating, suitable for coating various steel materials, such as stainless steel SUS304, SUS443, galvanized Z27 substrate, 55% aluminum zinc AZ150 substrate, magnesium aluminum zinc K27 substrate, and other corrosion-resistant materials.

Suitable for use on the roofs and exterior walls of coastal factories and industrial areas with severe corrosion, as well as in highly corrosive environments such as chemical industrial areas. Examples include: equipment and pipeline coverings in chemical and pharmaceutical plants, exterior and interior walls of raw material storage warehouses, roofs or exterior walls of residential buildings, general partitions, cold storage panels, fireproof boards, soundproof walls, windbreaks, etc.

Available sizes: 0.3~1.0mm*914~1250mm, with a tensile strength of 400N/mm2.

PVC painted steel sheet surfaces can be divided intoflat surfaceWithEmbossed patternAnimal hide pattern and lychee pattern.

coating

Function

- Excellent chemical resistance (acid and alkali resistance), chemical resistance, weather resistance, salt water resistance, and resistance to oils and greases.

- This product features a high film thickness coating, providing superior heat insulation performance compared to general paints and existing heat insulation coatings when used outdoors.

- It has excellent corrosion resistance and rust prevention capabilities.

- It has better scratch and impact resistance, can withstand sand and dust impacts, and reduce the spread of rust caused by paint film loss.

- This product provides excellent protection in environments with condensation and water vapor.

- Under low and normal temperature conditions (-15~45℃), the PVC coating has excellent processability and will not cause paint peeling problems such as embrittlement and cracking.

- The high film thickness coating process reduces costs. This product can achieve a coating thickness of 200μm on the front and 100μm on the back in one coat, which can effectively reduce production costs, labor costs and production time.

- With the protection of a high film thickness, the service life in general areas can reach 15 to 20 years.